ECM TOOLS PACK VERIFICATION

The integration of a simulation system for the computer-based testing and verification of a designed tool is also discussed.",

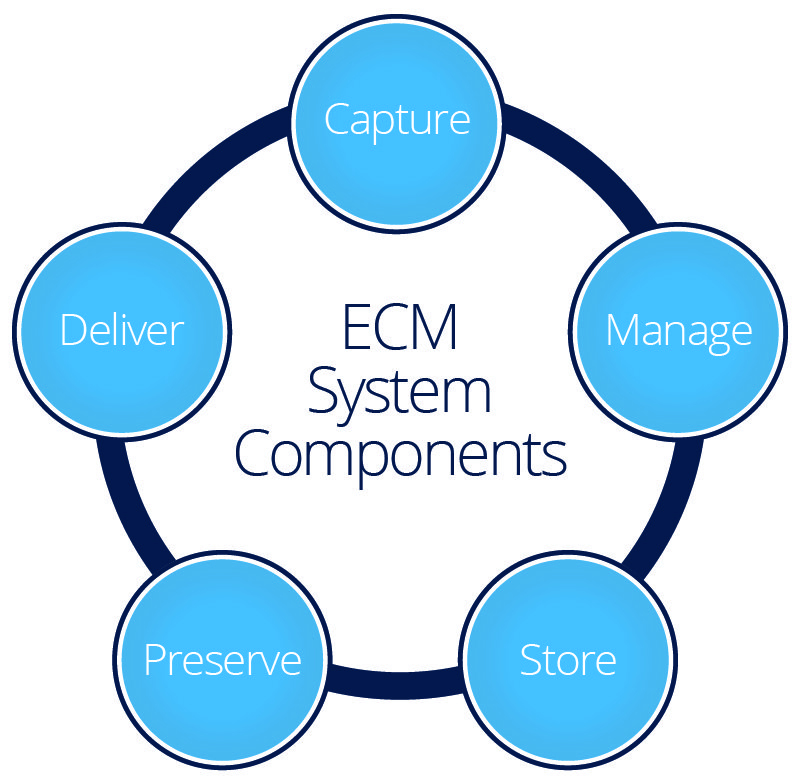

The scheme emphasizes the need for incorporating the optimization model, decision support system and a computer-aided process planning system in the tool design package. The paper also proposes an integrated approach for computer-aided tool design in ECM. The shape and size of the tools used during experimentation have been found to be in agreement with design. Experiments were conducted using an aqueous solutions of NaCl as electrolyte, low alloy steel castings and low alloy steel forgings as work materials, and brass as the tool material. Results of two-dimensional tool design for electrochemical drilling are presented. The finite element formulation for tooling design in electrochemical machining is outlined. The interdependence of different parameters, which is the main cause of the low success in tool design for ECM, is illustrated. These models based on the cos θ method, complex variable approach, empirical and nomographic approach, finite differences method, finite element technique, and boundary element method vary in the methodology employed to solve the Laplace equation (the cos θ method, and empirical and nomographic approaches do not use the Laplace equation), assumptions, applications, merits and limitations. The paper reviews different models proposed for the analysis problems (anode shape prediction) and design problems (tool design) in ECM.

ECM TOOLS PACK FULL

This, coupled with the initial high cost of ECM set-up, high wages of skilled operators and very high cost of components to be machined are the main obstacles to realizing the full industrial potential of ECM.

This results in low productivity of tooling design in ECM.

ECM TOOLS PACK TRIAL

The integration of a simulation system for the computer-based testing and verification of a designed tool is also discussed.Ībstract = "In practice the costly trial and error approach of designing and experimentally testing complex-shaped tools in electrochemical machining (ECM) is still followed.

In practice the costly trial and error approach of designing and experimentally testing complex-shaped tools in electrochemical machining (ECM) is still followed.

0 kommentar(er)

0 kommentar(er)